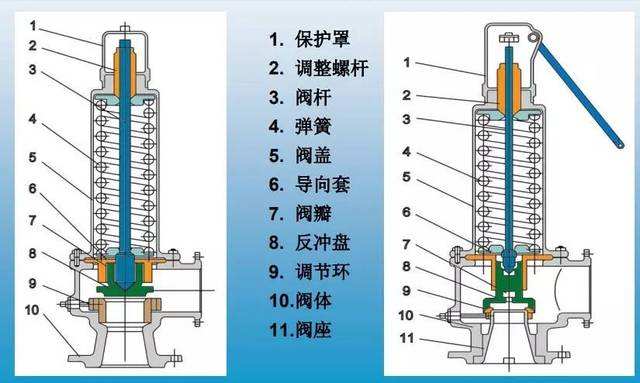

As the main control component of the fluid conveying system in the petrochemical industry, the sealing performance of the valve has a great influence on the energy saving effect of the whole system. Based on this, this paper first on the valve sealing structure of the factors affecting the application of the main points to be described, and then on the valve sealing structure of the improvement measures and improvement of the effect of exploration, hoping to deepen the exploration from the theoretical level, it will play an enlightening role in the actual work. In the process of using the valve, it is easy to have the problem of strength and seal failure, which will inevitably lead to the waste of energy resources, but also easy to have safety problems. The improvement of valve structural seal is the key work to improve the application quality of valve. The further research from the theoretical level will be helpful to the improvement of actual valve sealing structure. 1 The influence factor of the valve sealing structure and the application main point 1.1 the influence factor analysis of the valve sealing structure, the valve sealing degree needs to combine with its type and the nature to determine, the sealing degree of the valve also has a direct relationship with the valve material, equipment and process factors, any link appears quality problems, will inevitably affect the application quality of the valve. According to the scientific design standard, the sealing structure should be designed as a cone or a sphere. However, compared with the plane sealing structure, the sealing structure will have many adverse effects, and the sealing surface is easy to be scratched, as well as causes the maintenance processing to have many difficulties, like this also quite easy to increase the production cost and so on, the market sale will also have the influence. The sealing surface of the valve is designed as a cone or a sphere, there will be adverse factors, the plane sealing design is adopted, the sealing surface of the valve stem and the valve cover from the original conical shape will become a plane contact style, this way is less restricted, the accuracy of the device and equipment can be guaranteed, and the processing is relatively easy. Valve use time and valve opening and closing frequency is proportional, maintenance is also relatively easy. 1.2 The main points of the application of the valve sealing structure, the application of the valve sealing structure, we should pay attention to several aspects, can not let the valve in the condition of small opening, the starting of the valve needle is relatively slow. So when the opening is small throttle interval is relatively small, but also to be able to properly expand the locking mechanism pitch, increase the opening speed of the valve needle and lift, the working opening will further increase, can effectively extend the valve life cycle. In the practical application of the valve sealing structure, the medium temperature is easy to affect the service life of the valve, and the excessive medium temperature is easy to shorten the service life of the valve, should not be used as far as possible in the high-temperature medium valve work, pressure relief valve to increase the cooling device, which can effectively extend the life of the valve. To avoid impurities into them, which will affect the life of the needle valve. In addition, it is necessary to clean and filter high pressure media on a regular basis, add liquid to be filtered by a filter, use more times to properly shorten the use of the cycle, do a good job of cleaning the fuel tank, etc. , only from these aspects to get full attention in order to ensure the quality of valve sealing structure application.

2 Improvement Measures of valve sealing structure and improvement effect 2.1 improvement measures of valve sealing structure, improvement of valve sealing structure can improve the performance of valve sealing structure, industrial Producers Red Valve Sealing surface damage can be repaired through the corresponding high hair. There are commonly used grinding method, which is less damage to the valve sealing surface of the situation is more suitable, grinding stone and sandpaper to add a suitable abrasive can operate. It can also be applied by means of deep repair, mainly by turning. The application of this method is time-demanding, time-consuming and labor-consuming, and the hardness and quality of the material will be changed after deep processing, there are also structural and organizational changes. In the improvement and operation of the valve sealing structure, full attention should be paid to the scientific application of the method. The sealing surface of the valve is a hard material structure, which is not easy to be repaired, full threaded studs can be welded to the center of the disc end face, and the gasket can be customized to the spool either through a polytetrafluoroethylene or through a rubber plate support and a disc seal of equal size, the gasket and nut pressing device can be modulated to ensure the joint use of the gasket and the corresponding valve. In addition, for the improvement of butterfly valve sealing structure is also more important, this need to be described accordingly. At present, when the Butterfly Plate of the butterfly valve sealing structure is under positive pressure, the sealing effect is relatively good. When the medium exerts pressure on the butterfly plate, the sealing effect is affected accordingly, in particular, large-diameter valves on the more obvious. In the process of improving the sealing structure of the valve, it is necessary to pay more attention to the design of the structure so as to ensure a good effect of the bi-directional Metal Seal Butterfly Valve bi-directional seal. Lower Valve shaft and valve body fixed need tight transition fit, reduce fit gap, timely change the support point of the butterfly plate, which can effectively reduce the deformation of the butterfly plate under pressure. In addition, through the double eccentric spherical structure and the elastic thin-walled metal ring structure, to achieve the displacement compensation and elastic change compensation, when the valve is open, to be completely separated from the use of stainless acid-resistant steel without causing wear, avoid Rusting. When the valve is closed, the butterfly plate is pressed forward, which will make the displacement of the elastic metal seal ring larger, and the specific pressure value will rise, but it can guarantee the low specific pressure value and improve the reverse sealing effect. 2.2 The improvement effect of the valve sealing structure can be seen from the improvement effect of the valve sealing structure, after the actual application, has a relatively good application effect, will not affect the valve flow channel medium velocity, has a good sealing effect, for the valve sealing surface damage can not be repaired the problem has been effectively resolved. Valve internal leakage, through the wear and tear of the gasket to be replaced to solve the actual problem, in the cost is a good economy. The soft gasket and the hard seat sealing surface will form the sealing joint surface, through the improvement before the rigid hard seal becomes the soft-hard joint seal, thus can effectively increase the sealing area. When there is little damage to the sealing surface of the valve seat, it can be compensated by adjusting the opening degree of the valve screw and pressing the soft sealing gasket. For the improvement of butterfly valve seal structure, also has a good effect, to ensure the quality of structural design, to extend the service life of two-way Metal Seal Butterfly Valve, also can reduce the use of unit valve replacement frequency, this can effectively reduce the overall cost, reduce the intensity of work, from the overall increase in work efficiency. In order to ensure the effectiveness of the valve sealing structure, it is necessary to improve the protective measures. This needs to ensure that the length of welding bolts on the valve plate can not be too long, otherwise it will cause the phenomenon of sealing surface overhead, sealing effect will be affected. To select the appropriate adjustment pad, the thickness should be slightly less than or equal to the disc sealing surface of the step height, so that the gasket and disc sealing surface can tightly fit, in the same plane. The use condition of fluid medium should be fully considered to avoid medium corrosion and high temperature deformation to affect the use effect of valve sealing structure. When the damage of the sealing surface of the valve seat is serious, the valve seat should be discarded. The spool can be improved and matched with the valve seat of the same specification. Adjust the valve to do a good mark to effectively avoid, Mengkaimengguan, can not affect the life of the gasket. The application of the improved method can improve the effect of the valve sealing structure. It is suitable for the cut-off valve with simple streamline structure. Conclusion, in a word, for the improvement of valve sealing structure application, can improve the application quality of valves. The application of the valve to do a good job in the corresponding protection, which is also an important way to extend the service life of the valve. Through the improvement of the valve sealing structure and the related application research above, we can know more about the improvement of the valve sealing structure in theory, and provide the corresponding reference for the actual improvement work. The smooth implementation of the improvement can ensure the safety of the valve work, it is necessary to proceed from the safety point of view to do a good job in the corresponding improvement.